Nuokang Mold has high-efficiency and high-precision processing equipment, including CNC machining centers, milling machines, lathes, wire cutting machines, EDM, etc. After years of hard work, the company has a strong technical force and a group of experienced designers. The entire production team will use CAD/CAM/CAE software to ensure that the manufactured molds have high precision and long life.

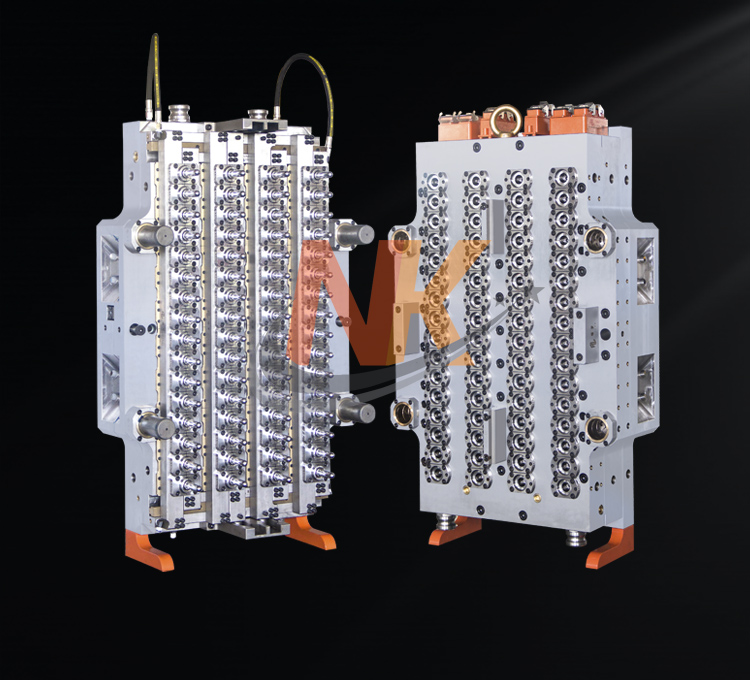

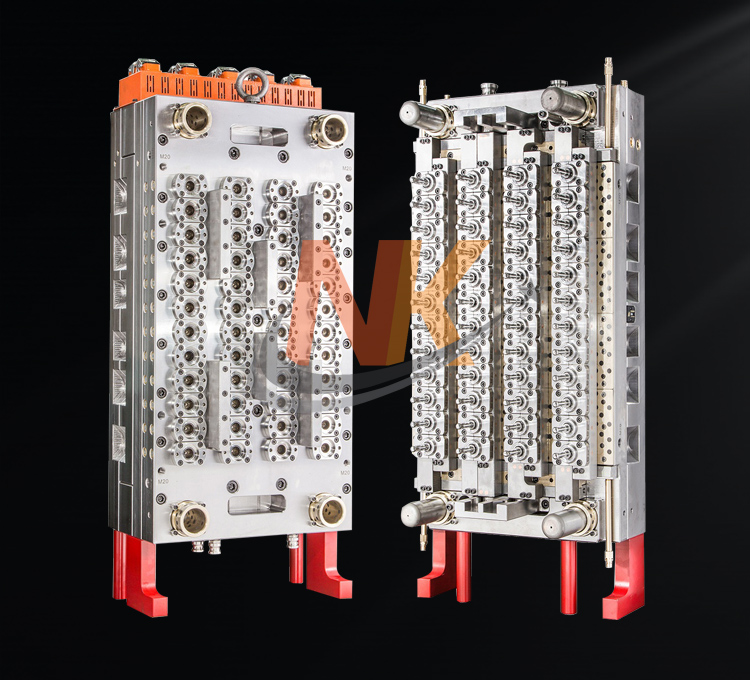

48-cavity air-sealed PET preform mold

48-cavity air-sealed PET preform mold1: Professional and technical experience in preform mold cavities ranging from 1 to 96 cavities.

2: The preform mold uses CAD software to design the preform shape according to the bottle to ensure the molding quality of the bottle.

3: The thread opening material of the preform mold is made of imported nitrided steel, manufactured according to international standards, with high hardness, each thread is ventilated, and has a long service life without deformation.

4: Preform mold core and cavity are made of corrosion-resistant steel, which is durable.

5: The preform mold adopts advanced hot runner design, so that each cavity can be independently temperature controlled, heated, and the temperature is uniform.

6: Cut-free gate preform mold, saving labor and raw materials.

7: The temperature of the hot runner nozzle is controlled separately. (To solve the problem of whitening and wire drawing at the bottom during the production process).

8: Needle-valve self-locking preform mold: each core, cavity, independent double self-locking, adjustable eccentricity, reduce eccentricity, ensure product concentricity, high precision. The mold has a long service life.

9: Support sample and drawing processing, provide new product development, one-stop service for injection molding processing!