Nuokang Mold has high-efficiency and high-precision processing equipment, including CNC machining centers, milling machines, lathes, wire cutting machines, EDM, etc. After years of hard work, the company has a strong technical force and a group of experienced designers. The entire production team will use CAD/CAM/CAE software to ensure that the manufactured molds have high precision and long life.

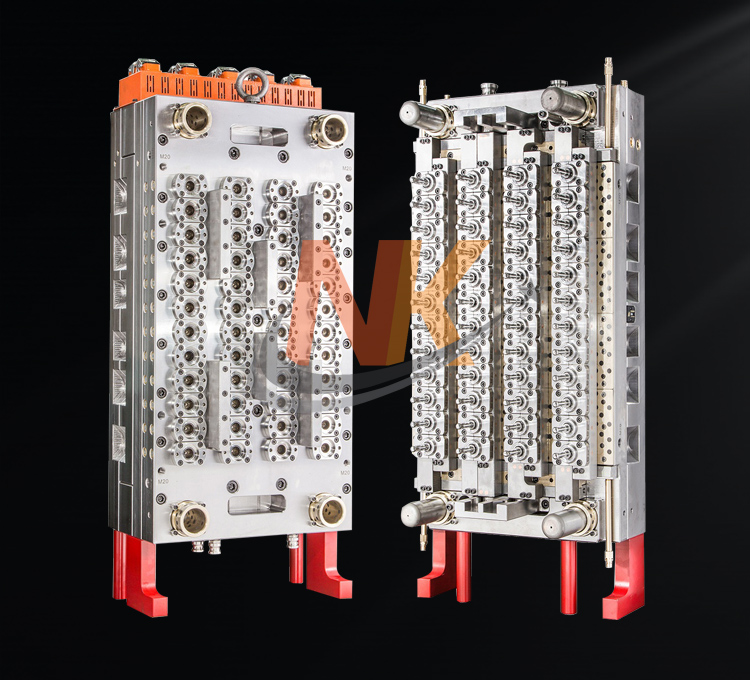

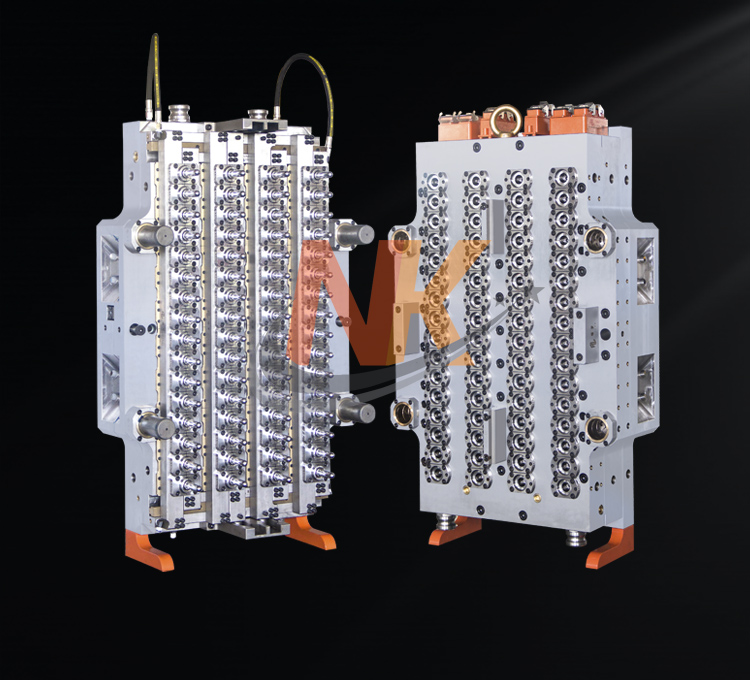

64 cavity preform mold

64 cavity preform mold1. The hot runner adopts PID control system, which is characterized by automatic repair and automatic protection functions, which can prolong the service life of the electric heating device;

-The temperature is controlled within 1°C to ensure that the raw materials are not burned in the hot runner, and the finished product rate can reach more than 99%;

-The new nozzle design makes the mold easier to maintain, the thimble part of the nozzle, the heating part, the heat insulation part, and the thermocouple can be easily replaced without disassembling the mold, which is beneficial to reduce downtime and save maintenance costs.

2. Cooling system

-The spiral cavity cooling water channel makes the cooling effect stronger.

-The cooling water channel on the threaded port and the slider enhances the cooling effect.

-Exquisitely designed central distribution plate, cooling water can be evenly introduced into each cavity, and all preforms can be effectively cooled evenly and quickly.

3. Hot runner

- The hot runner with excellent balance performance ensures the flow and pressure of PET melt in all cavities are uniform.

-PET melt channeling minimizes shear and IV losses and allows PET melt to flow evenly to all cavities.

- Optimal heat distribution keeps the acetaldehyde (AA) content in all cavities stable.