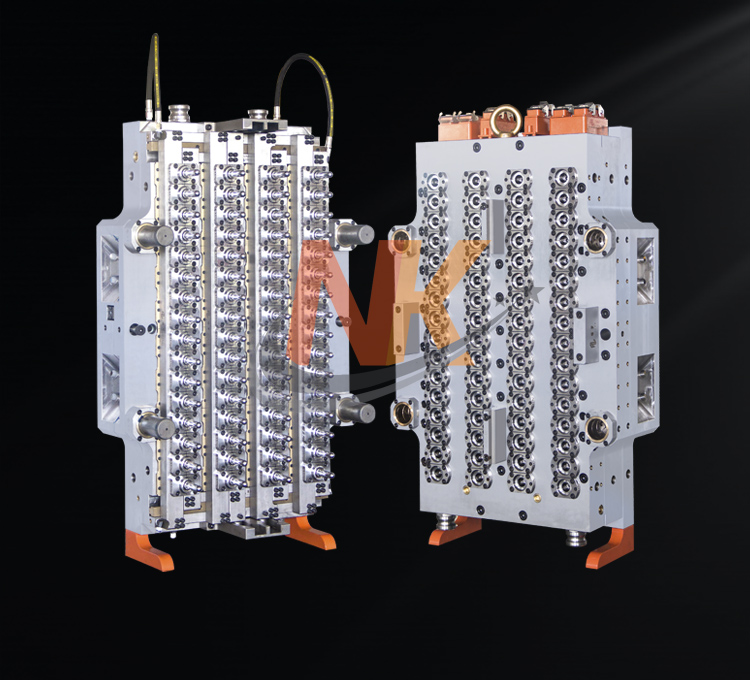

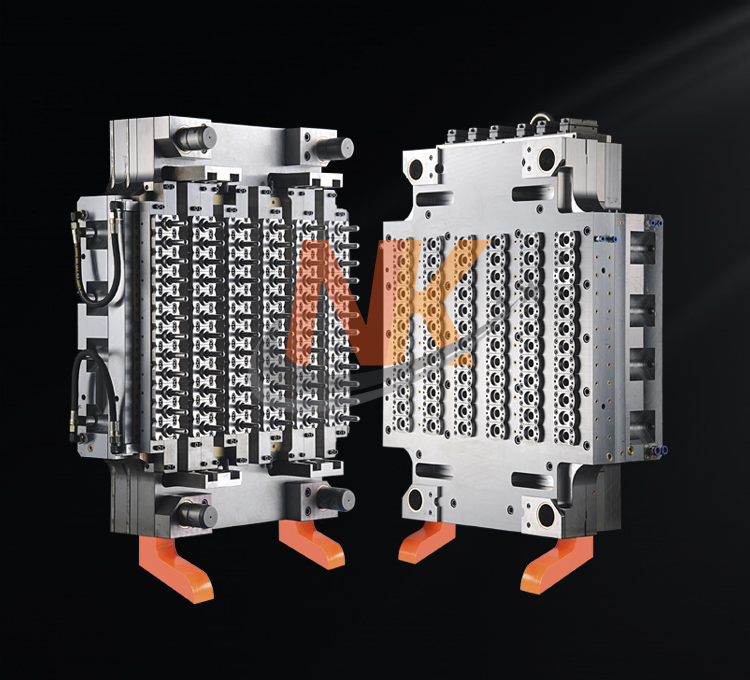

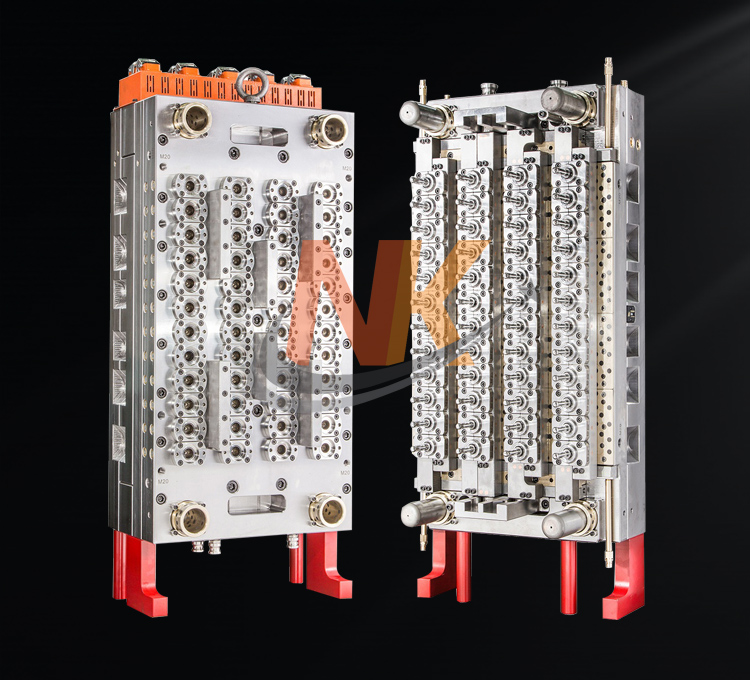

Only focus on preform molds! High-quality, high-efficiency multi-cavity preform molds. PET preform mold designation 2-14/16/24/32/48/64/72/96 cavity and jar mold, reliable PET preform mold supplier. Free customized service, 3D preform sample design, professional manufacturer, 100% satisfaction.

About nuokang

Professional customized PET preform mold

The company adopts CAD/CAM/CAE technology utilized by major production equipment to improve quality and develop new products. According to the requirements of the ISO 9001 quality system, strict corporate standards and production processes are implemented to provide customers with high-quality products. High quality advanced product. The company has built a solid reputation worldwide. Products are sold to more than 100 countries.

No design, no model

Rigorous scheme design, mass production after one trial run

Through the analysis of material properties and product feasibility, such as wall thickness, deformation degree, glue injection position, etc., pre-judgment in advance potential problems.

Maintain close communication with customers, understand product functional requirements and precautions from the perspective of customers, such as requirements for joint lines, appearance Face requirements, etc.

Strict design review system and checklist inspection. Before design and during the design of the scheme structure discussion meeting, the designer self-checks according to the checklist; After design, review with the manufacturing department.

Focus on details and focus on control

Quality inspection of each link to detect mass production problems in advance

Incoming materials, processing, final molding, quality inspection of each link, to find problems in advance.

Each project has a complete set of quality inspection reports for easy traceability, such as appearance requirements.

Precipitated mold development, design, injection molding experience in industries such as preforms and caps.

Cycle control and early delivery

Provide progress reports at any time to let customers know the status at all times

Each project is equipped with a project manager who strictly follows the schedule to control the project cycle.

Provide weekly progress reports and mold photos for each project to keep customers informed of status.

Provide mold test videos online to let customers understand the operation of molds.