Nuokang Mold has high-efficiency and high-precision processing equipment, including CNC machining centers, milling machines, lathes, wire cutting machines, EDM, etc. After years of hard work, the company has a strong technical force and a group of experienced designers. The entire production team will use CAD/CAM/CAE software to ensure that the manufactured molds have high precision and long life.

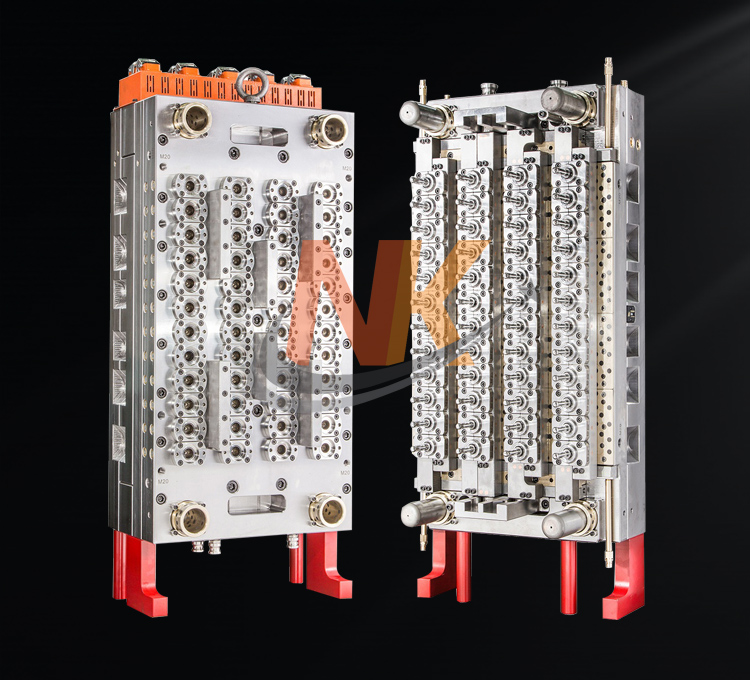

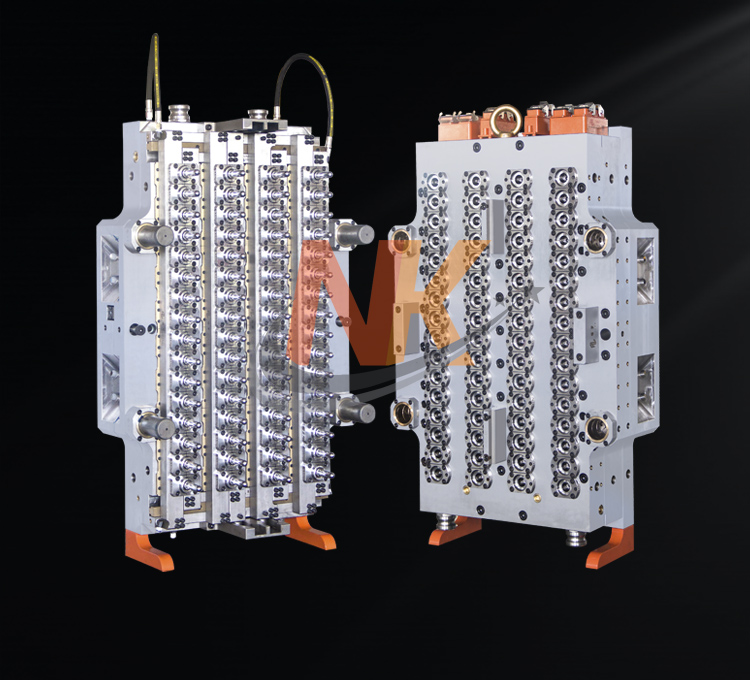

48-cavity air-sealed PET preform mold

48-cavity air-sealed PET preform mold1. Mold features:

1. We specialize in the production of needle valve moulds, which do not require manual cutting.

2. The use of advanced hot runner system ensures that the AA value of the product is at a low level.

3. Reasonable cooling water channel design strengthens the cooling effect of the mold and effectively shortens the injection molding cycle.

2. Material selection:

1. The main parts of the mold are made of imported S136 material (Sweden-Sabak).

2. The mold base material adopts imported P20 material and electroplating treatment, which improves the corrosion resistance of the mold and prolongs the service life of the mold.

3. The heat treatment of the parts is processed in a vacuum furnace imported from Germany, and the hardness of the parts is guaranteed to be at HRC45°-48°.

4. Advanced processing equipment:

The company has introduced a number of machine tools imported from the United States and Japan, such as machining centers, CNC lathes, EDM, etc., to ensure the machining accuracy of the parts and make the parts have good interchangeability. , the weight error is less than 0.3g, 2-5 molds can be produced in one minute, and the service life can reach 2 million mold times.