Nuokang Mold has high-efficiency and high-precision processing equipment, including CNC machining centers, milling machines, lathes, wire cutting machines, EDM, etc. After years of hard work, the company has a strong technical force and a group of experienced designers. The entire production team will use CAD/CAM/CAE software to ensure that the manufactured molds have high precision and long life.

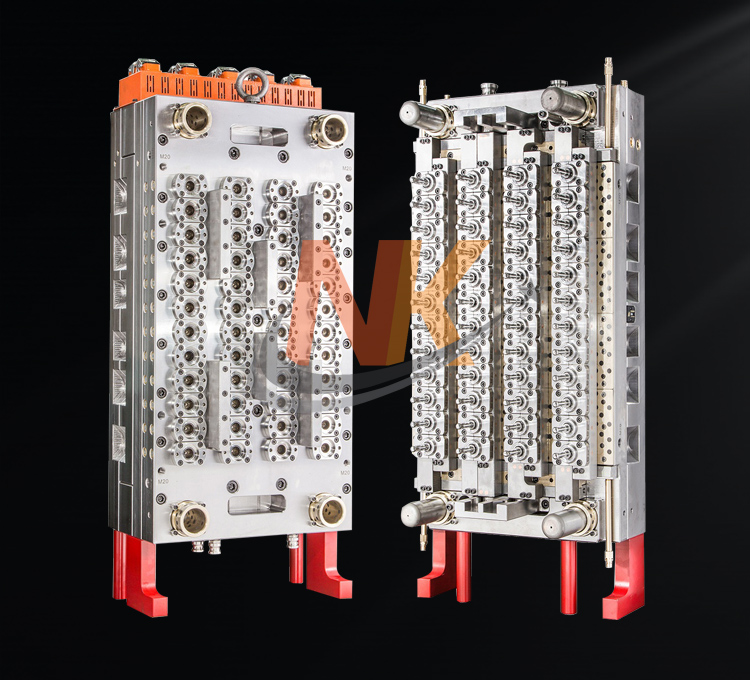

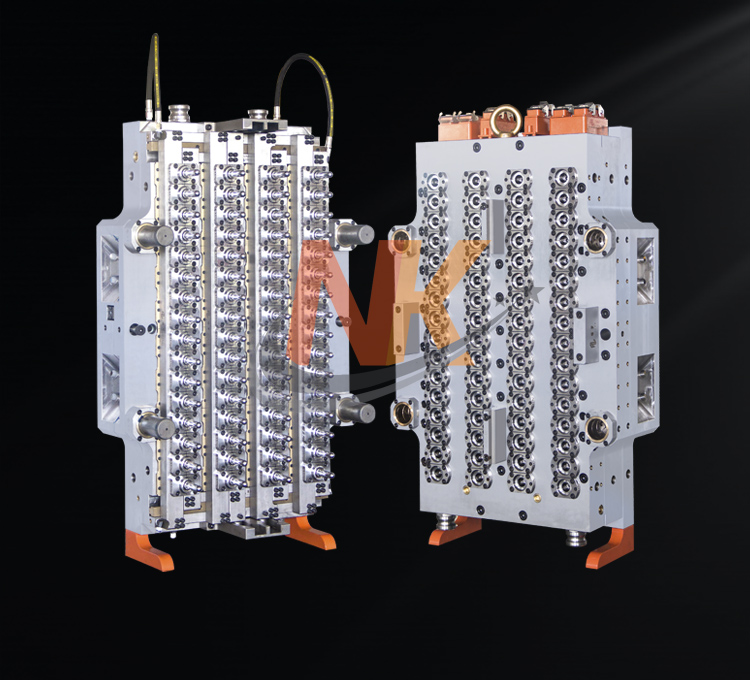

12 cavity preform mold

12 cavity preform mold1. Imported S136 steel cavity, core, and threaded neck are used, and the heat treatment hardness can reach HRC 48-50; all formworks are heat-treated with a hardness of HRC 30-35.

2. Advanced mold design technology:

Each cavity is independently self-locking, using high-precision Japanese SYATEM.

To ensure the low body ratio and precision of the product.

Each die has spare inserts for durable parts that are interchangeable.

In order to improve and achieve high production efficiency, we always design the best cooling system, and can match a cooling machine for each mold.

3. Advanced and precise valve hot runner and temperature controller ensure the reliability of production and high light transmittance and brightness of the product.

4. The sliding mold is made of copper, the bottle body meets the food safety standard, and the life of the mold is guaranteed to be more than 3 million times.