ABOUT US

A company focusing on the research and development and manufacturing of preform molds

Taizhou Huangyan Nuokang Mold Co., Ltd. is located in Huangyan District, Taizhou City, Zhejiang Province, the "hometown of moulds", close to 104 National Highway, Taizhou Exit of Yongtaiwen Expressway and Taizhou Civil Aviation Airport, with convenient transportation. Since its establishment, it has been focusing on the design of PET preform molds and caps and the development and manufacture of corresponding molds, which are widely used in beverages, food, edible oil, condiments, candies, cosmetics, cleaning supplies, medical supplies and other fields.

The company adopts the CAD/CAM/CAE technology utilized by the main production equipment to improve quality and develop new products. According to the requirements of the ISO 9001 quality system, strict corporate standards and production processes are implemented to provide customers with high-quality products. High quality advanced product. The company has built a solid reputation worldwide. Products are sold to more than 100 countries.

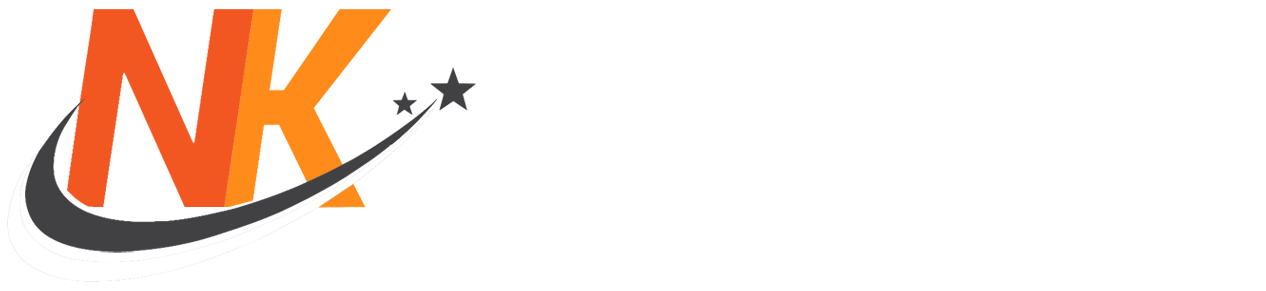

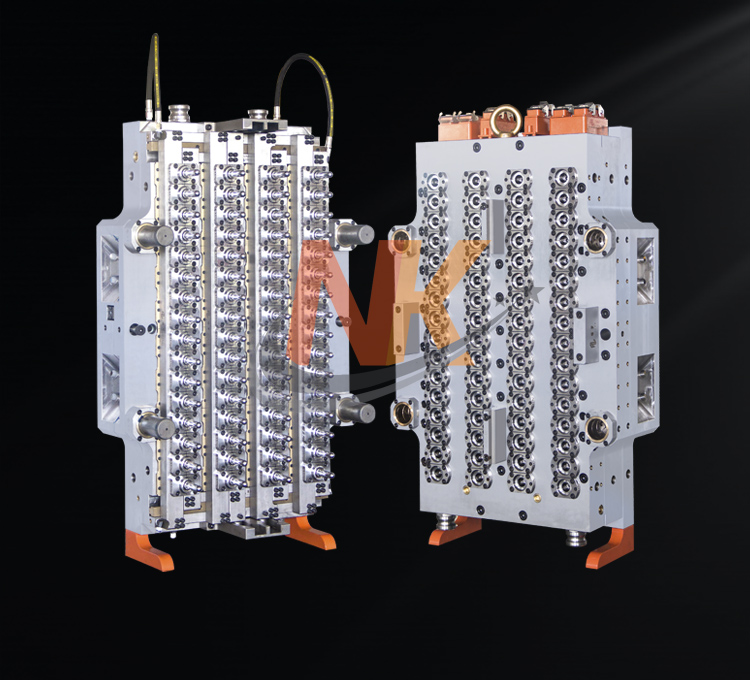

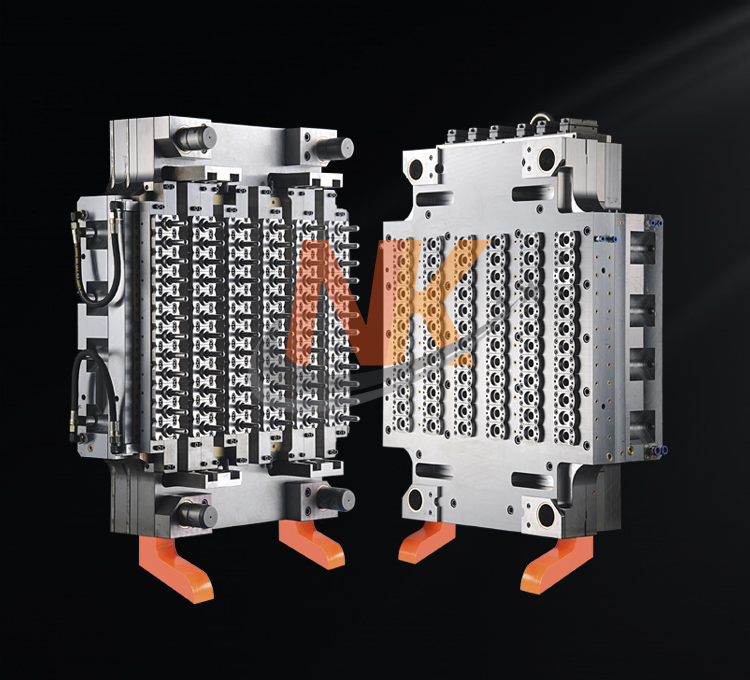

All of our molds are designed with 3D computer graphics, bringing together our experience in molding and designing thousands of molds, so that the finished preforms have uniform thickness, stable size, high success rate, and greatly reduce the defective rate of finished products. No matter what bottle type or brand machine, Nuokang can provide a perfect matching mold.

All of our molds are designed with 3D computer graphics, bringing together our experience in molding and designing thousands of molds, so that the finished preforms have uniform thickness, stable size, high success rate, and greatly reduce the defective rate of finished products. No matter what bottle type or brand machine, Nuokang can provide a perfect matching mold.

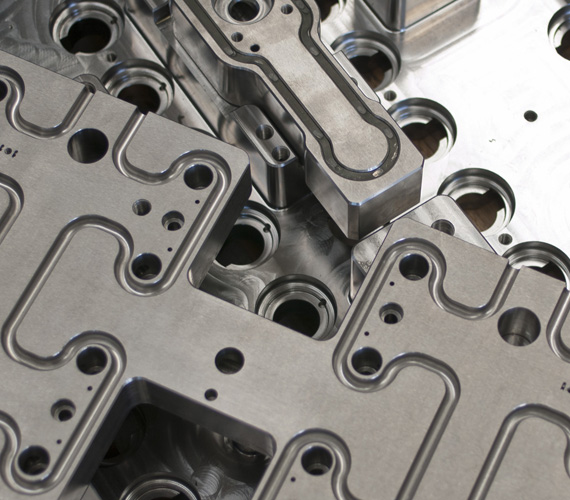

From raw materials, heat treatment, surface treatment, manufacturing tools to final products, a precise quality control system runs through the entire production process to ensure product quality.

From raw materials, heat treatment, surface treatment, manufacturing tools to final products, a precise quality control system runs through the entire production process to ensure product quality.

The preform molds all adopt the hot runner system, the output is fast, the molding time is shorter, the waste is greatly reduced, and the competitiveness of the enterprise is increased. The PET preform mold adopts needle valve hot runner system technology, which effectively reduces the wear and maintenance costs of parts, and reduces power consumption by 10% to 15%;

The preform molds all adopt the hot runner system, the output is fast, the molding time is shorter, the waste is greatly reduced, and the competitiveness of the enterprise is increased. The PET preform mold adopts needle valve hot runner system technology, which effectively reduces the wear and maintenance costs of parts, and reduces power consumption by 10% to 15%;

Services We Do

PET preform mold designation 2-14/16/24/32/48/64/72/96 cavity and jar mold, reliable PET preform mold supplier.