Nuokang Mold has high-efficiency and high-precision processing equipment, including CNC machining centers, milling machines, lathes, wire cutting machines, EDM, etc. After years of hard work, the company has a strong technical force and a group of experienced designers. The entire production team will use CAD/CAM/CAE software to ensure that the manufactured molds have high precision and long life.

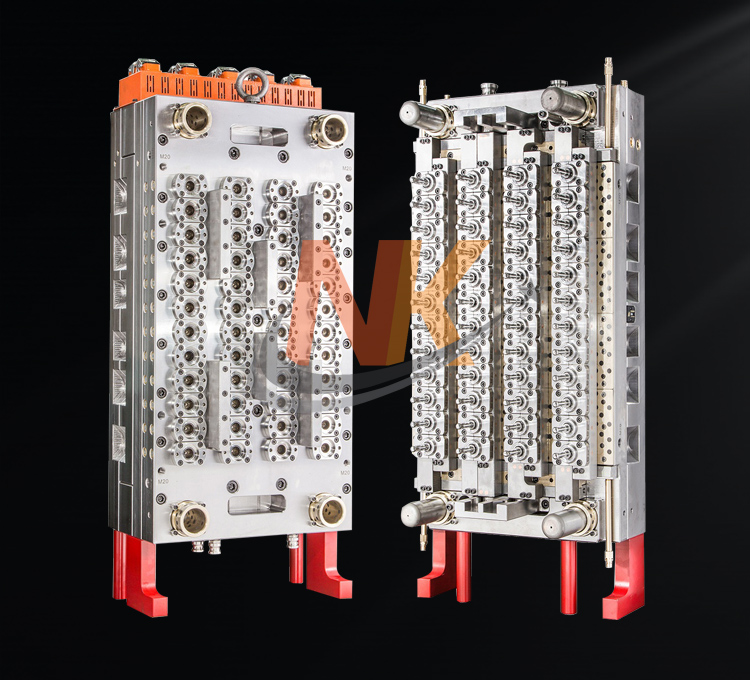

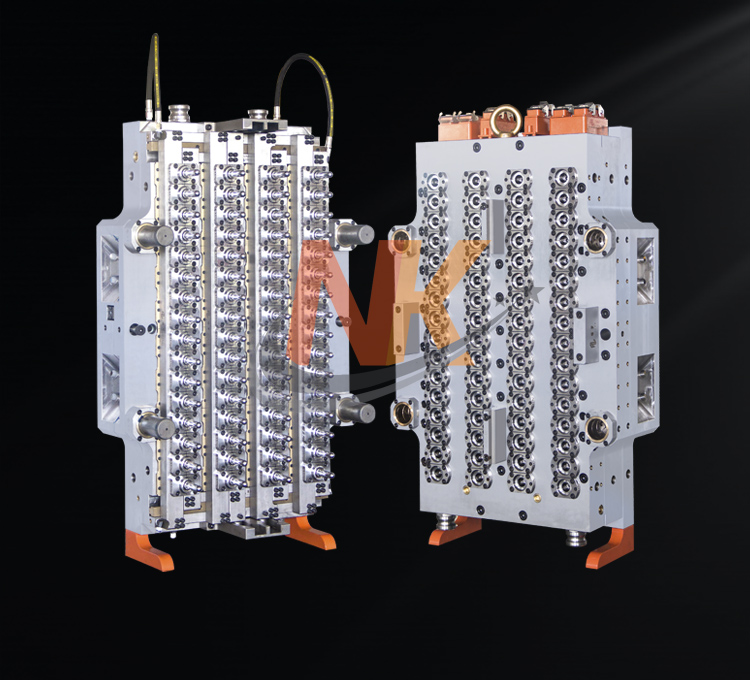

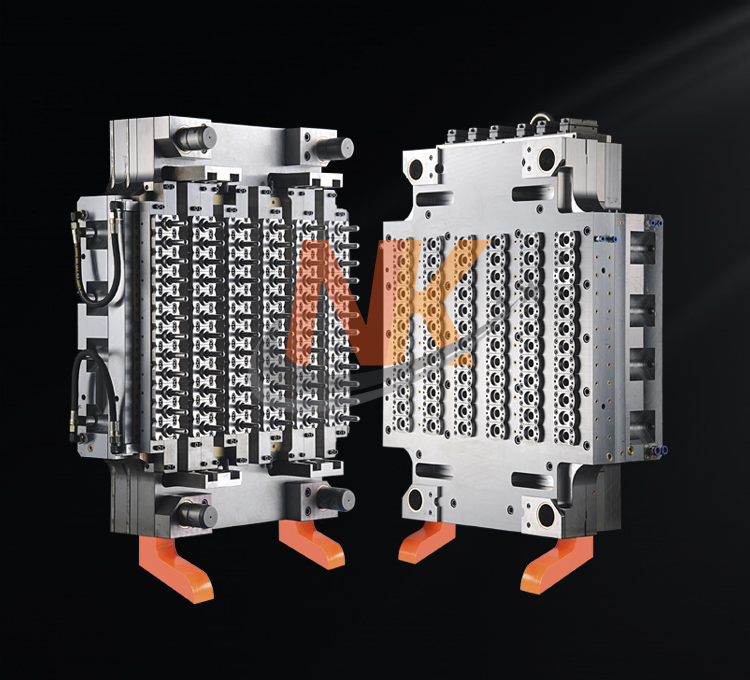

72-cavity PET preform mold manufacturing

72-cavity PET preform moldWe are one of the reliable companies in this field, offering PET preform molds with advanced PET preform mold design technology.

1: material

Custom Material 632: Better than FS136 with higher nickel and chromium content.

Toughness, rust resistance, and whitening effect are obviously improved.

The mold base is made of HRC 38~40 stainless steel or P20 (pre-hardened).

2: Stack design of SelfLock type

Before closing the mold, the parting seam is locked in place by a locking ring to minimize parting line wear on the cavity side and core side, thereby extending the burr-free life of the parting line.

3: cooling system

The core adopts fountain or spiral cooling structure.

Spiral waterways are used for milling outside the cavity, improving cycle efficiency and reducing cleaning time.

The neck is drilled with cross cooling channels.

Each plate is individually designed with circulating cooling channels.

An optimized cooling layout is used to ensure fast and efficient heat exchange between steel and water and supports fast cycle times to save energy costs.